FAST AVAILABLE ITEMS

Items which are available faster are marked by 8 in the catalouge.Though it does not indicates any definate perioud of

delivery,these items can be manufactured faster than the other items of its range.For example,pipe section ps18/1000

can be supplied faster than any other pipe section of 450DN.This is because of following reasons:

Semi finish or raw material for these items will be always available.

Method of production of these items are set.

Being fast moving items,these items may be available ex-stock with us.

REPAIRS

Though any damaged glass equipment can be repaired,mostly it is not economical to do so.Generally,the repair which involves

less than a third of its original work,is worth to carry out repairing.Repair work is costly because:

a, It generally required greater skill than making a new one.

b, Since it involves high risk of total breakage,the risk of total loss of time spent on its repairing goes alongwith.

c, The work involved in receiving a damaged equipment,identifying it throughout the handeling,cleaning it,estimating its

repairing charges,re-estiming the repairing charges in case damage extends etc are relatively expensive.

d, Each job require invidual attention throughout the execution.

However,while sending an equipment for repairing,following care must be taken:

a, Inform the nature of breakage and get an estimate of repairing charges in advance to avoid the loss of transportation

expenses in case it is uneconomical to go for repairing.

b, Since repairing takes longer time to fit into production scheduled and completion of repairing is highly uncertain,it is

generally suggested to arrange for a substitute equipment to continue the work.

c, Equipment to be repaired should be clean.Since it can be cleaned before sending it for transportation.This also makes it

safer to transport.

d, Pack with extra care since cracks in glass have a tendency to extend with every jerk.

e, If possible,send broken pieces alongwith it.

f, Generally repairing work is accepted only for the equipment manufactured by us, and are repaired at owners's risk only.

DIMENSIONS WEIGHTS AND SPECIFITIONS

In this catalogue dimensions,weights and other specifications are taken more or less in accordance with corning.This is to

keep the flexibility of maximum interchange ability.however,some difference are unavoidable due to local manufacturing conditions.

All the odd dimensions are rounded off.

All the dimensions and weights are approximate.The specifications given in the catalogue are intended to present a general

description of the items.since manufacturing of glass equipment involves all manual operations,certain tolerances are

obvious and permissible while passing the items through quality control.

CATLOGUE REFERENCES

To avoid queries and delays in delivery,please always quote the catalogue reference in your order.

MODIFICATIONS

We reserve the right to carry out technical modifications of product and data mentioned in this cataogue as and when require.

STANDARDS PRACTICED

DIN ISO 3585

DIN ISO 3586

DIN ISO 3587

DIN ISO 4704

BSEN 1595

DIN ISO 718

INTRODUCTION

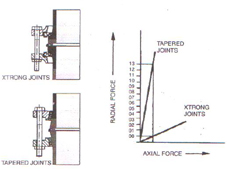

Tapered glass joints are predominantly used in industrial glass equipments.This design has a high ratio of radial to axial force,

which frequently leads to breakage while tightening the flange joints.

A cylinder can withstand a much higher axial force than radial force plus glass has a very high compressive strength.

We at GARG recognized these features and by our innovative design practices developed XTRONG joints.the XTRONG joints

are so designed that the harmful radial stresses are dramatically reduced.For a given axial force the radical forces are

14 times lesser than that in tapered joints.

XTRONG joints are practically many times stronger than convintion tapered joints as far as tightening of joints is concerned.It is

tested that a XTRONG joints does not break even at a torque of 20nm,as against tapered joints,which starts breaking at 6-7nm torque

at times it may happens that because of over tightening a metal backing flange breaks or the threads of nut-bolts give way

but XTRONG glass joint remains intact.

Most of the old glass installations in general contain equipmentS with tapered glass joints.XTRONG joints are fully compatible

with these tapered joints.i.e,an XTRONG equipment can replace another tapered equipmentand vice versa in any existing unit.

This interchangeability makes XTRONG design more adaptable in general conditions and change over cost is negligible.

XTRONG joints

XTRONG joints have been developed,to arrest the frequent breakage and leakage problems.The XTRONG joints are so designed that

the harmful radial stresses are dramatically reduced.For a given axial force the radial force are 14 times lesser than in

tapared joints.

In addition to reducing the stresses,the XTRONG joint has the following advantages:

- The ovality of the glass flange,present due to manufacturing process,has virtually no effect because the backing flange isn,t in direct contact with the periphery.

- Continuous re-tightening of the backing flange or insect,due to bolting force & temperture effects,hence dismanting is easy.

- The XTRONG joint is leak-tight at all design temperatures & pressure,even with temperture cycling and frequent plant start-up as it is possible to tighten the joints upto a tightening torque of 20Nm as against 6-7 Nm tightning torque in tapered joints.in some cases the metal backing flange breaks but nothing happens to the glass components!

With so many benefits and particularity low breakage risk, we have adopted Xtrong design for all equipments manufactured

by us. Xtrong is widely accepted and adopted by users as well as manufacturers of Glass Equipments in india.

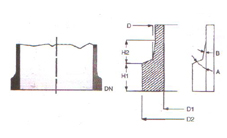

DIMENSIONS OF XTRONG ENDS

DN |

D2 |

D1 |

D |

H1 |

H2 |

A |

B |

25 |

41 |

27 |

34 |

13 |

8 |

65 |

9 |

40 |

56 |

40 |

49 |

14 |

9 |

65 |

9 |

50 |

69 |

52 |

62 |

16 |

11 |

65 |

9 |

80 |

98 |

79 |

91 |

18 |

12 |

65 |

9 |

100 |

132 |

108 |

123 |

20 |

17 |

65 |

9 |

150 |

184 |

159 |

166 |

22 |

19 |

65 |

9 |

225 |

258 |

229 |

233 |

24 |

26 |

65 |

9 |

300 |

340 |

308 |

315 |

24 |

26 |

65 |

9 |

400 |

463 |

405 |

425 |

25 |

35 |

65 |

9 |

450 |

535 |

455 |

499 |

25 |

50 |

78 |

9 |

600 |

684 |

600 |

640 |

25 |

60 |

65 |

9 |

| |

|

|